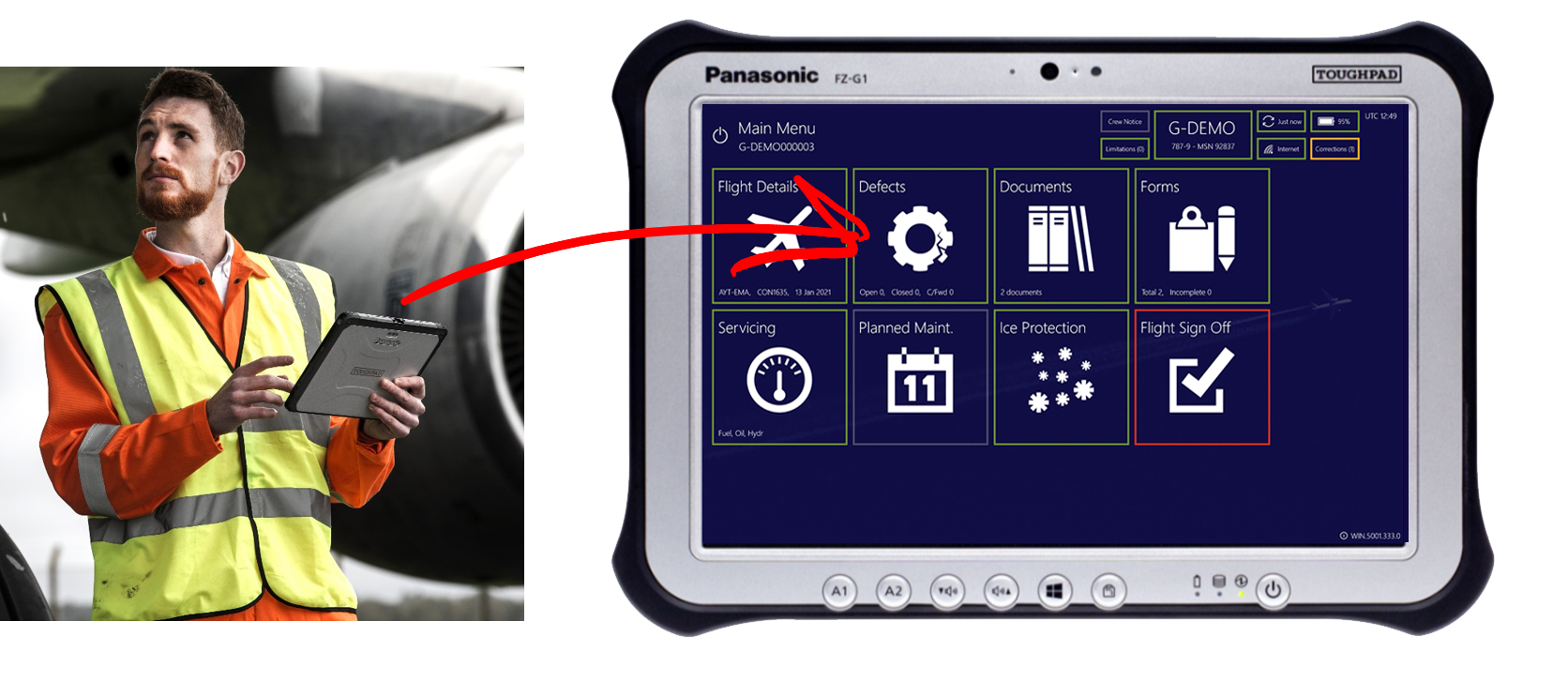

The aircraft technical log page (TLP) is the most complicated and important form that is used within an airline. It is used to record all issues before, during and after a flight sector. Issues requiring rectification become defects which can then be closed or deferred.

The TLP uniquely bridges Operations and Engineering. It is a legal document which requires various signatures from both pilots and engineers for every flight of an aircraft.

In the event of an aircraft incident, the copy of the TLP left on the ground is the first document that is reviewed by the Accident Investigators. This contains the certified condition of the aircraft prior to the flight being investigated. There are serious legal consequences if a TLP copy has not been left on the ground before every flight!

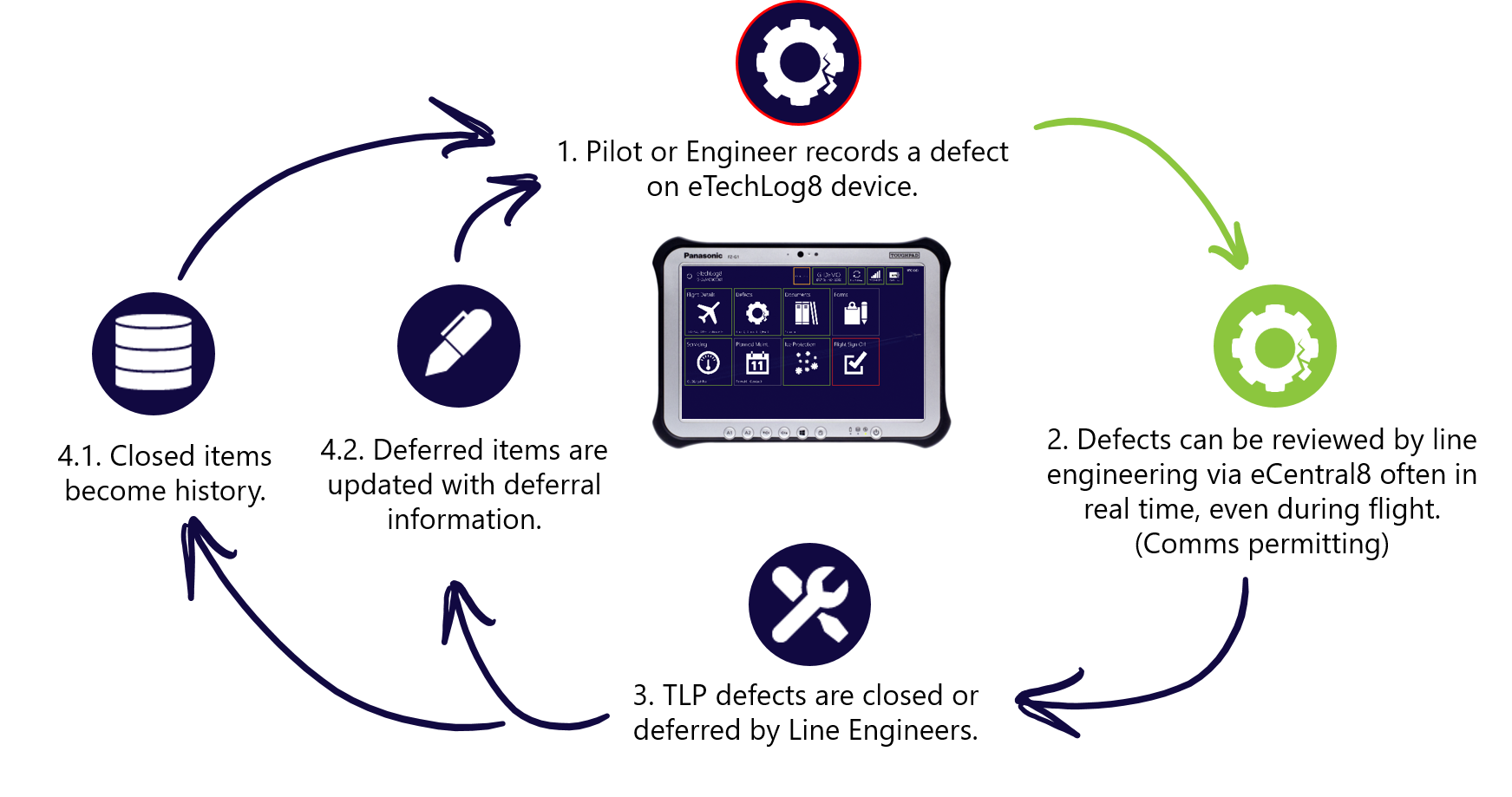

The Defect Status of the aircraft is a major part of the TLP. All defects that are found whilst the aircraft is on Line (whenever it is not in the Hangar for heavy maintenance) are recorded in eTechLog8. Line defects are recorded on the open TLP as soon as they are discovered. These defects must either be fixed and closed or evaluated as safe to defer for later rectification. Often deferring defects requires reference to the aircraft Minimum Equipment List (MEL). Actioning defects must be done by a suitably certified engineer (or, in rare instances, a pilot), with the Authority of an EASA or FAA Part 145 Maintenance Organisation.

Due to the serious nature of the requirements documented above, the defect functionality within eTechLog8 is substantial. Indeed defect functionality accounts for more than half the eTechLog8 application if measured in lines of code.

Defects can be recorded from two sources:

Pilots observe a defect during flight operations. These are referred to as Pilot Reported Defects (PIREP’s).

Click here to watch a 3 minute demo of recording PIREPs.

Alternatively Engineers discover defects whilst the aircraft is on the ground between flights. These are referred to as Maintenance Reported Defects (MAREP’s).

Click here to watch a 3 minute demo of recording MAREPs.

Defects may also be observed by Cabin Crew, these are facilitated via eCabinLog8. These defects must be assessed by the Pilot and either recorded as a PIREP defect on the TLP or Acknowledged as cosmetic and referred to Cabin Services for rectification that does not require a 145 approved engineer to certify, for example a carpet stain or stained seat covers.

Deferring Defects

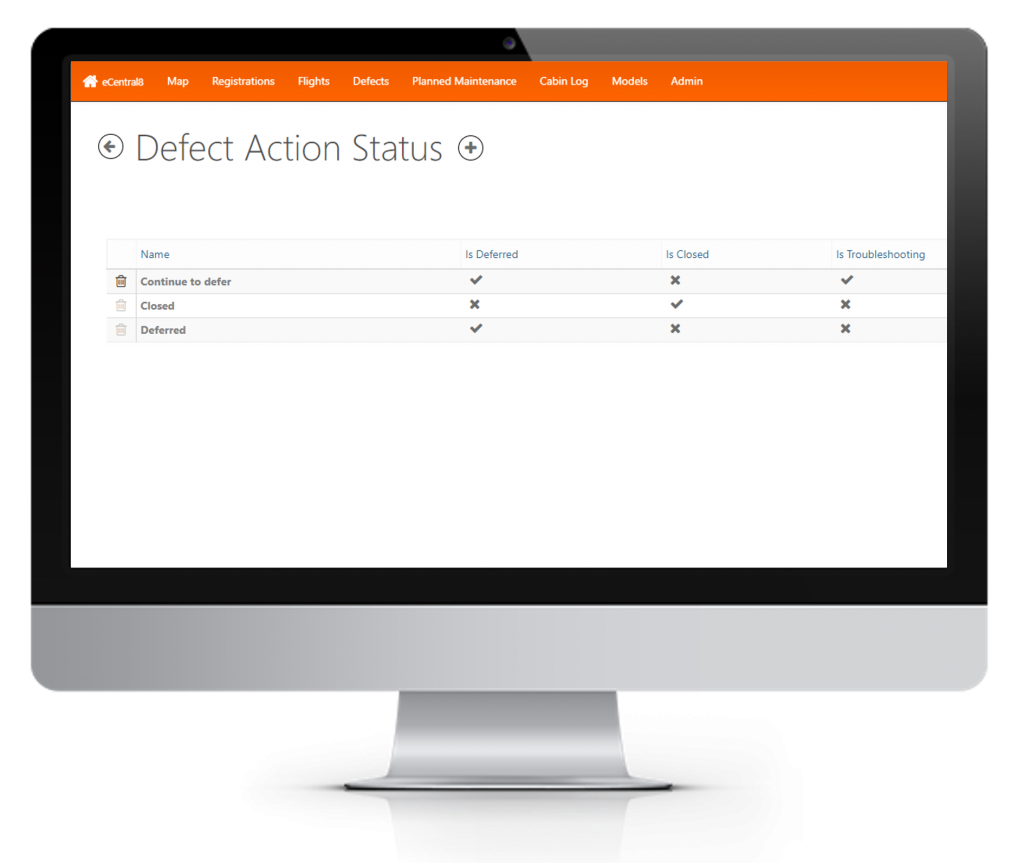

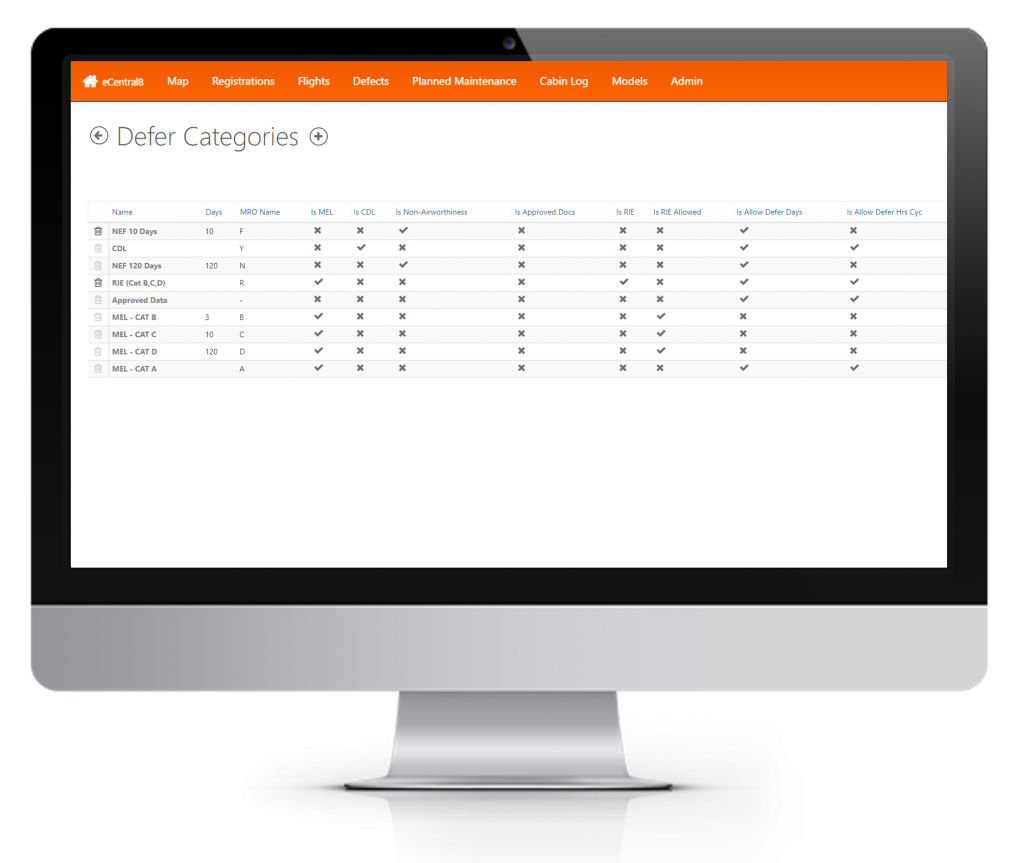

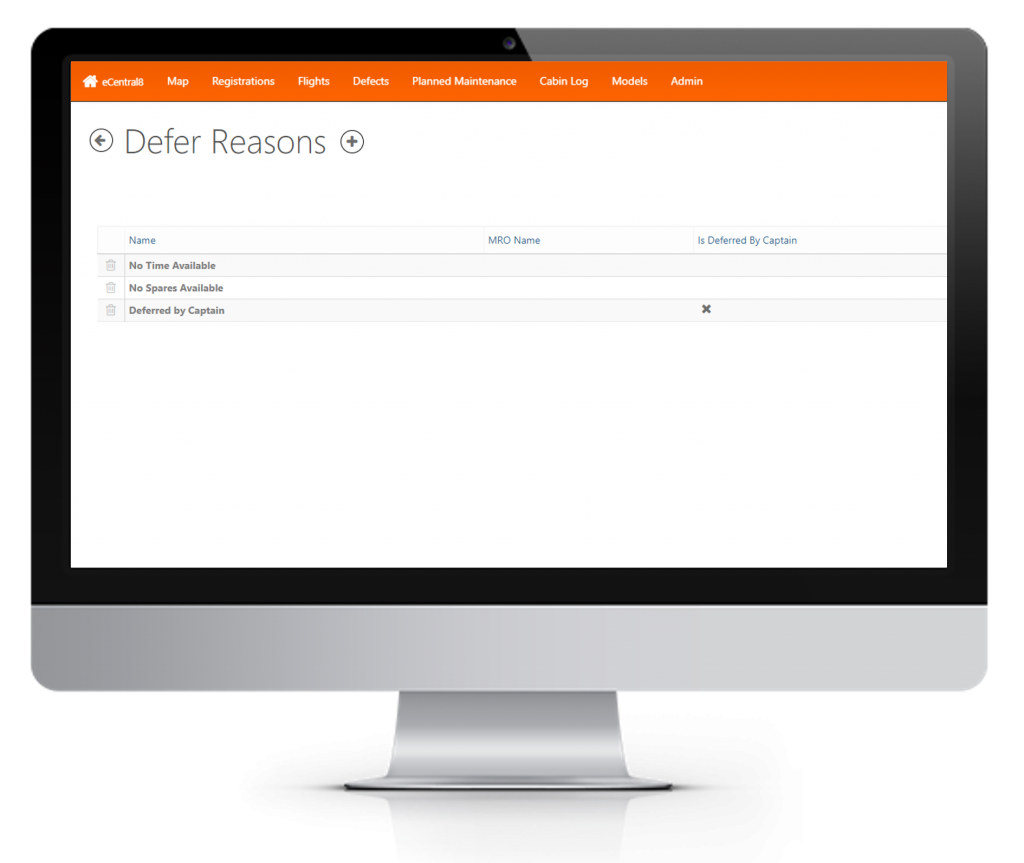

At the core of eTechLog8 there is a comprehensive Defect Deferring system. The system is configured on eCentral8, where the following can be setup to suit the airline.

When eCentral8 is configured, the choices are transmitted to the device where they are used during the defect deferral process:

Depending on the Defect category selected, a deferral period can be specified, this may be in flying hours, elapsed hours or days, landings and even Flight Days. The engineer is responsible for deferring the defect by the correct MEL Category and the appropriate deferral period as specified therein.

In exceptional cases a defect may be deferred a second time this is referred to as a Repair Interval Extension (RIE). This extension can only be used in exceptional circumstances and usually written confirmation is required from the Local CAA/NAA. Whenever an RIE is used, a copy of the RIE approval document from the NAA is usually stored with the TLP and in eTechLog8 it is normal for a photo of the document to be taken against the defect.

Pilots Reviewing Current Open Deferred Defects prior to Flight Acceptance

Prior to accepting an aircraft for a given flight the Captain is required to Sign a Flight Acceptance statement. This is accomplished in the Flight Sign Off tile of eTechLog8.

Part of the acceptance criteria is for the pilot to review the current open deferred defects, so the pilot can be aware of any Operational or Maintenance restrictions that may be in place for the aircraft being Accepted. eTechLog8 provides easy access to the open deferred defects list and also provides an amber warning tile if there are any Operational or Maintenance restrictions active.

Once the pilot is satisfied the aircraft is serviceable and fueled sufficiently for the intended flight, the pilot will sign the Acceptance and transmit the completed TLP to the ground server prior to flight. If it is not possible to transmit the completed TLP electronically then a paper copy must be printed and left on the ground prior to flight.